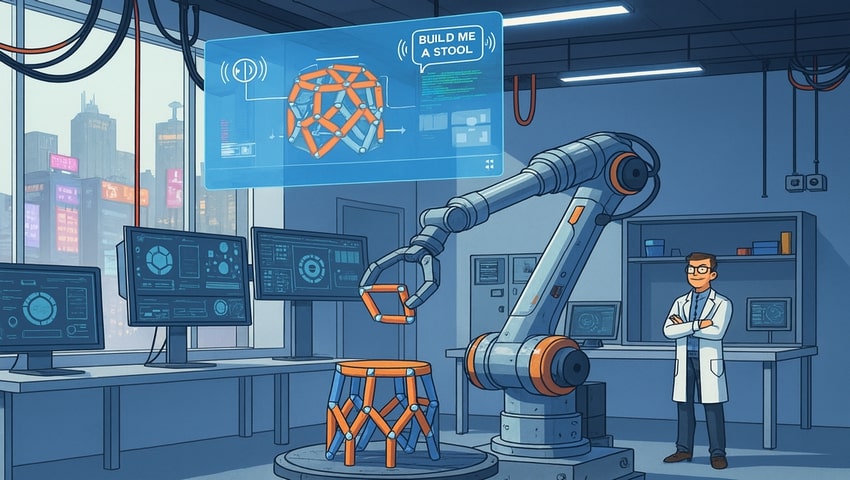

The road between science fiction and actuality is turning into more and more blurred, because of researchers at MIT who’ve developed a system that may flip voice instructions into bodily objects inside minutes. The “Speech-to-Actuality” platform integrates pure language processing, 3D generative AI, geometric evaluation, and robotic meeting. The platform permits customers to fabricate furnishings, purposeful, and ornamental objects on demand with out the necessity for 3D modeling or robotics experience.

The system’s workflow begins with speech recognition, which converts the consumer’s voice enter into textual content. Massive-scale language fashions (LLMs) interpret textual content to establish requested bodily objects whereas filtering out summary or non-executable instructions. The processed requests function enter to a 3D generative AI mannequin, which generates a digital mesh illustration of the item.

As a result of AI-generated meshes are inherently incompatible with robotic meeting, the system applies a part discretization algorithm that partitions the mesh into modular cuboctahedral items. Every unit measures 10 cm on a facet, is designed to interlock magnetically, and may be reversibly assembled with out instruments. Geometric processing algorithms then confirm meeting feasibility, addressing constraints similar to stock limitations, unsupported overhangs, vertical stacking stability, and connections between elements. Directional rescaling and connection-aware sequences guarantee structural integrity and stop collisions throughout robotic meeting.

An automatic path planning module constructed on the Python-URX library generates pick-and-place trajectories for a 6-axis UR10 robotic arm with a customized gripper. The gripper’s passive alignment indexer ensures correct placement even with slight part put on. Meeting is finished layer by layer in an order that prioritizes connectivity to make sure a grounded and secure construction. A conveyor system recirculates elements for subsequent builds, enabling sustainable round manufacturing.

The system demonstrated the speedy meeting of quite a lot of objects, together with stools, tables, cabinets, and ornamental objects similar to letters and animal collectible figurines. Objects with massive overhangs, excessive vertical stacks or branched constructions are efficiently fabricated because of constraint-aware geometric processing. Calibrating the pace and acceleration of the robotic arm additional ensures dependable operation with out inflicting structural instability.

Though the present implementation makes use of a ten cm modular unit, the system is modular and scalable, permitting part miniaturization for high-resolution builds and the opportunity of integration with hybrid manufacturing strategies. Future iterations could incorporate augmented actuality and gesture-based controls for multimodal interactions, in addition to absolutely automated decomposition and adaptive modification of current objects.

The Speech-to-Actuality platform represents a know-how framework for bridging AI-driven generative design and bodily manufacturing. The mixture of language understanding, 3D AI, discrete meeting, and robotic management allows the speedy, on-demand, and sustainable creation of bodily objects, offering an avenue for scalable human-AI co-creation in real-world environments.